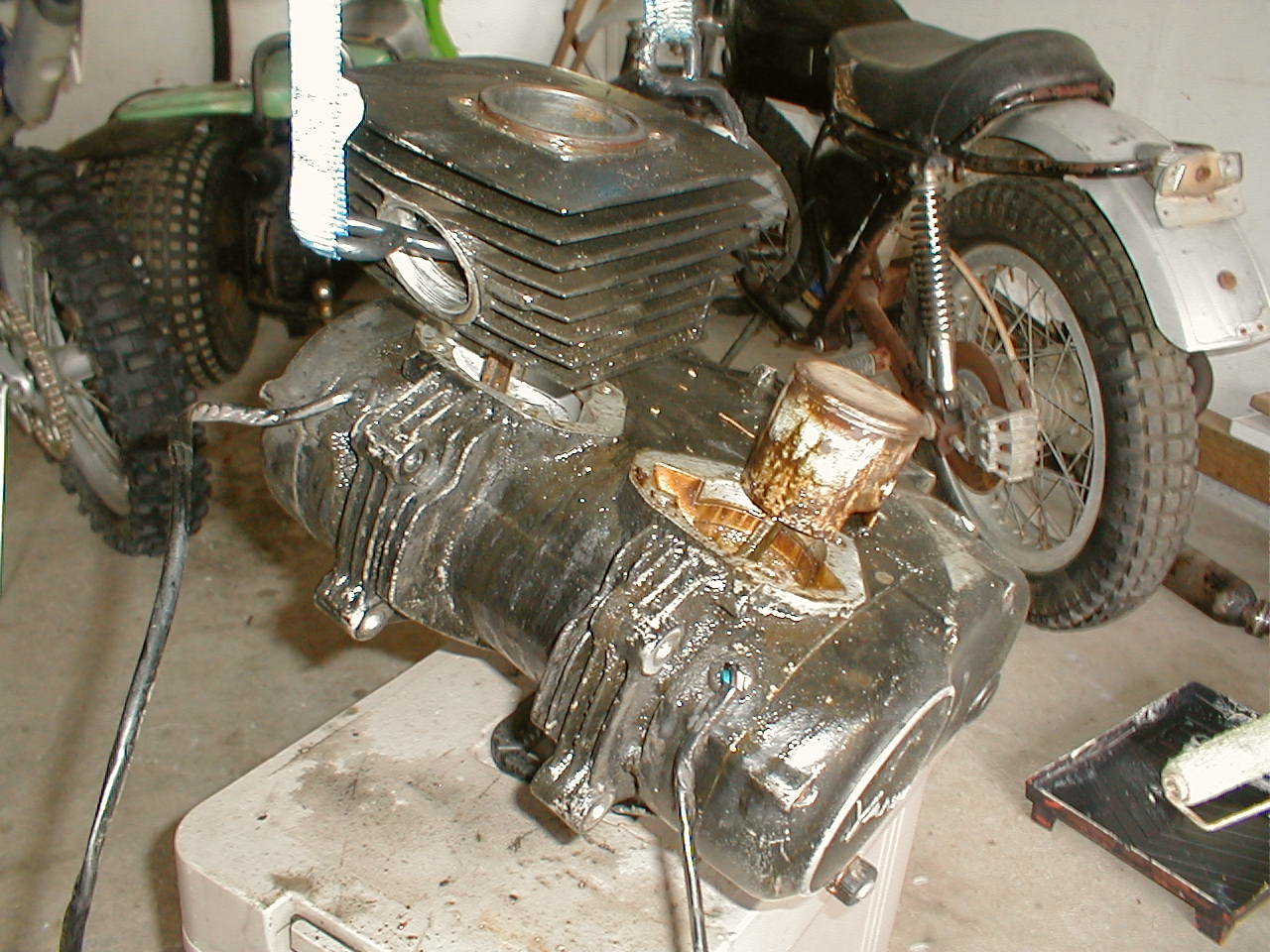

1973

Yankee Restoration Project

Pictures

taken 10/31/2003

Friday

was a day off, and I decided that this was

THE

day the pistons were going to come out of the

cylinders,

in one piece, or in many pieces.

A

lift was made from tie downs, so the whole weight

of

the engine could be supported by one cylinder.

A

wooden ram was cut from 4 x 4 stock, same

size

as the cylinder. I noticed the end of the ram

wasn't

even, and almost trimmed it off with the

circular

saw. It then occurred to me that having

one

side hit the piston first, would concentrate

pressure

in a smaller area, and the ram could be

turned

as it was hit with a 5 lb. sledge hammer.

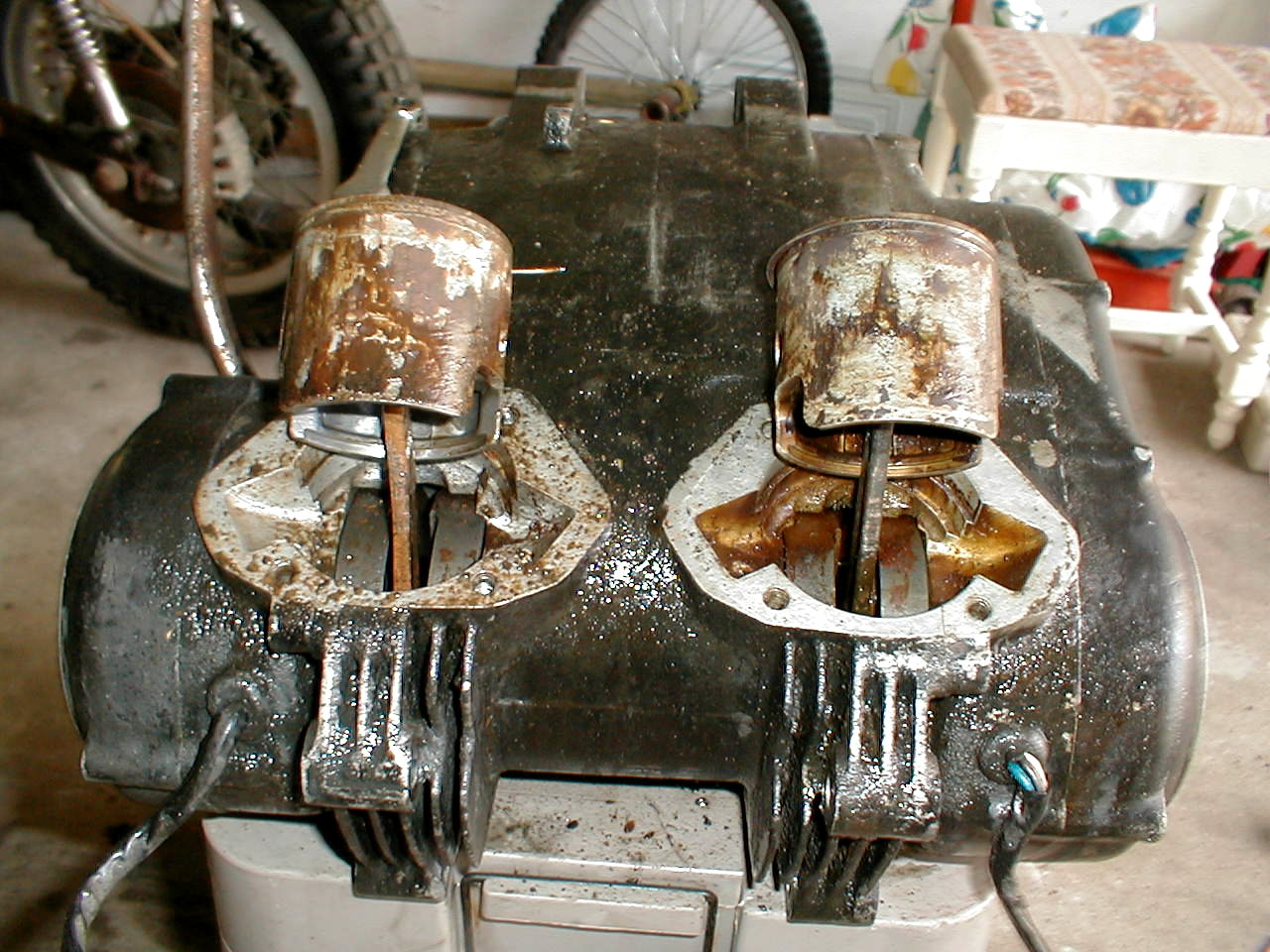

The

engine was resting on a work table, and

then

was lifted almost completely off the

table,

by one cylinder. This way, the weight

of

the engine was helping to extract the

piston

from the cylinder. The nylon straps

absorbed

some of the shock, and isolated

the

hammering to one piston, rod, and

main

bearing.

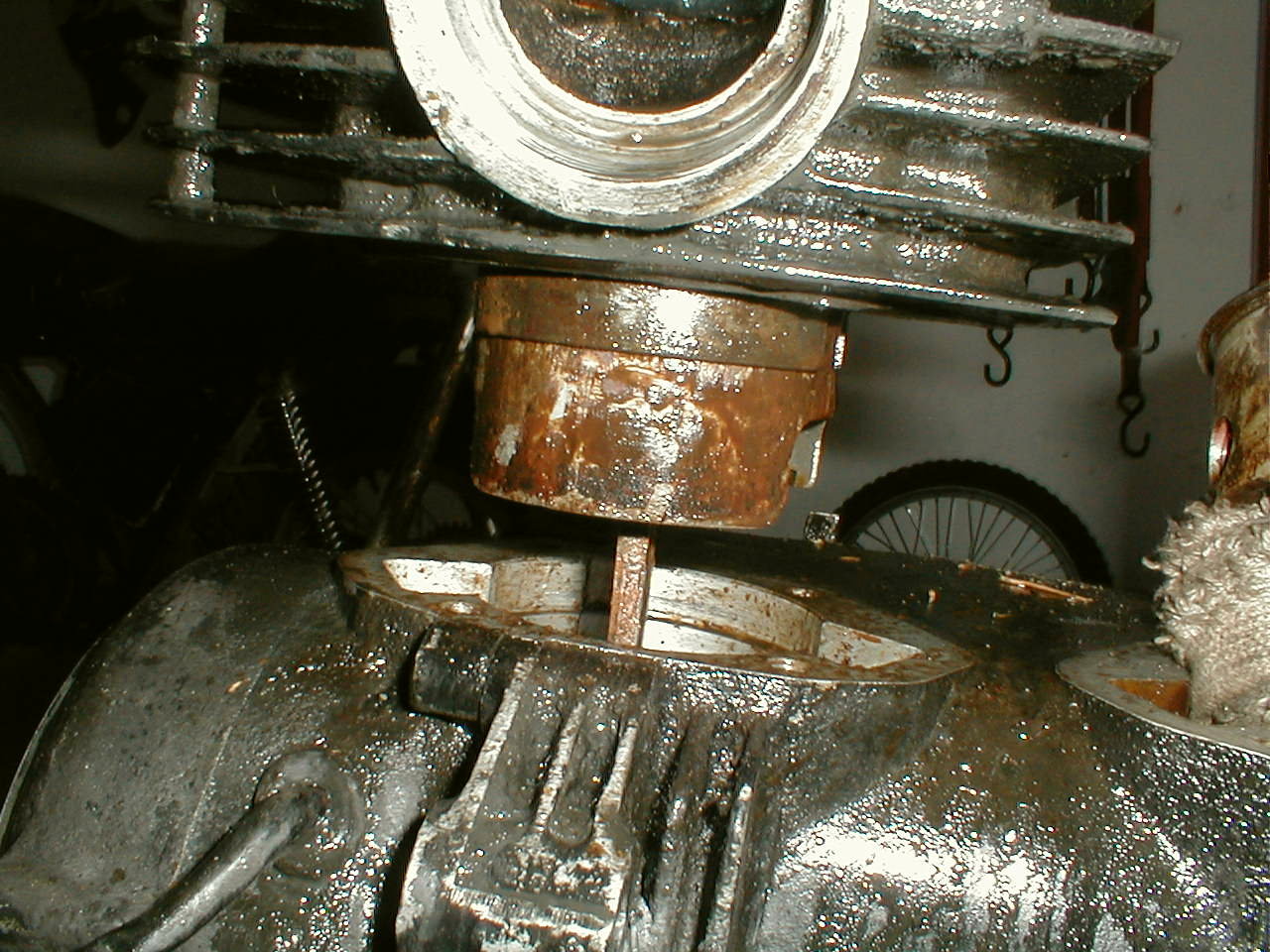

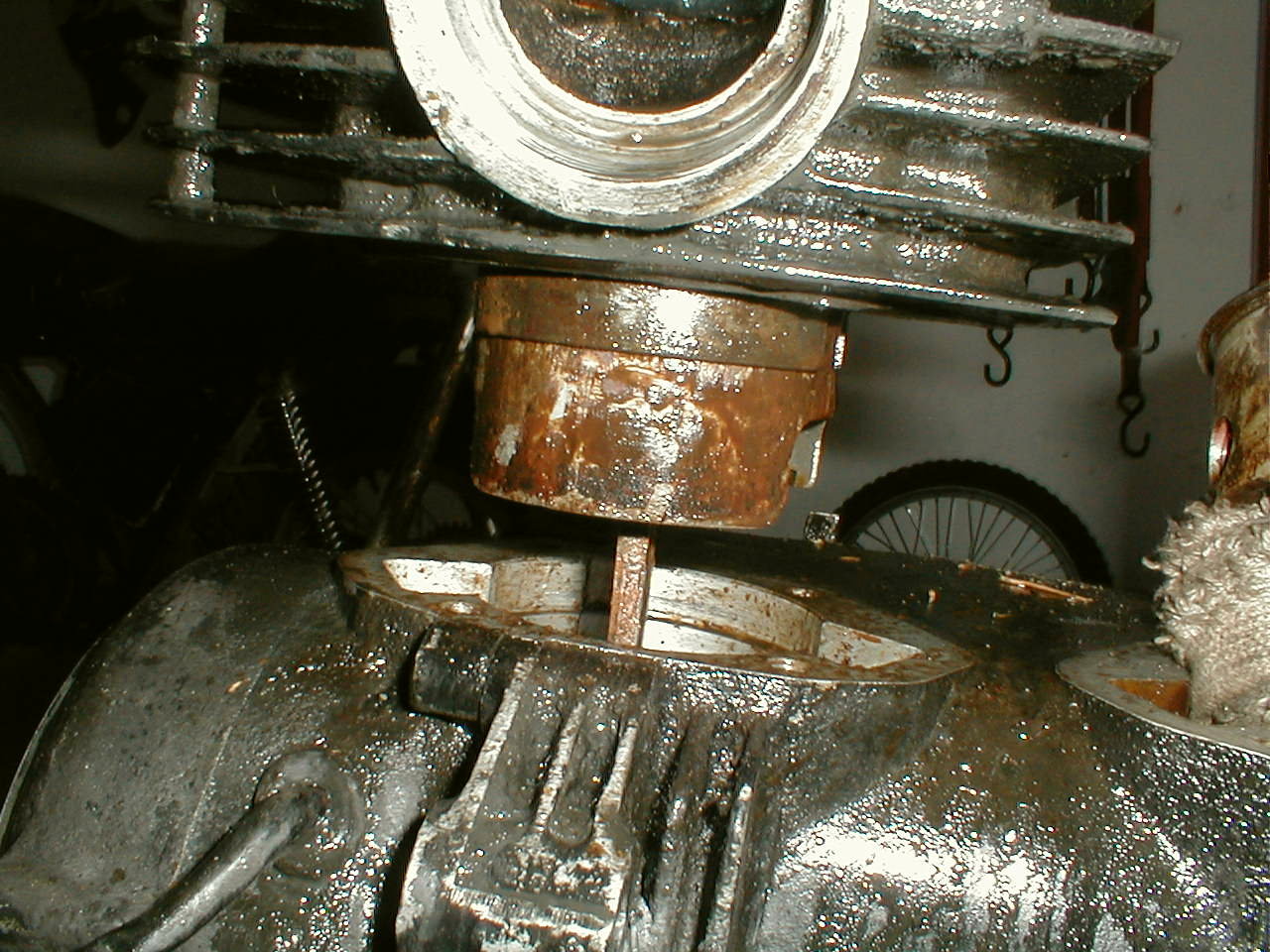

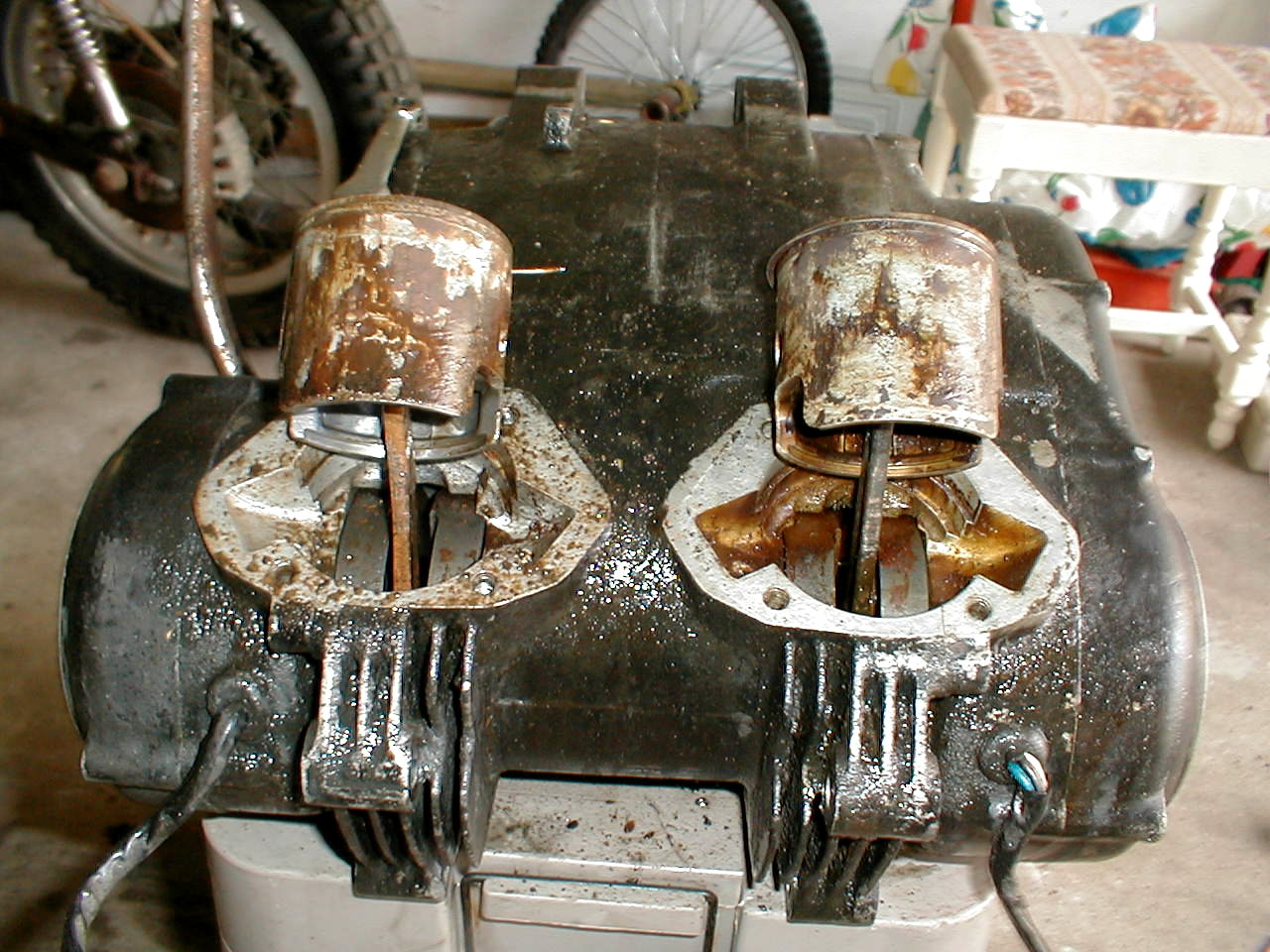

Each

side took about 15 minutes of solid pounding,

to

remove each piston. The gunk left in the engine

when

it was stored collected in the worn spaces of

the

bore, and didn't want to slide past the tight

spots

(bottom of bores) in each cylinder. One

set

of rings came off easy, the other set is soaking

again

back in the sauce, along with the carburetors.

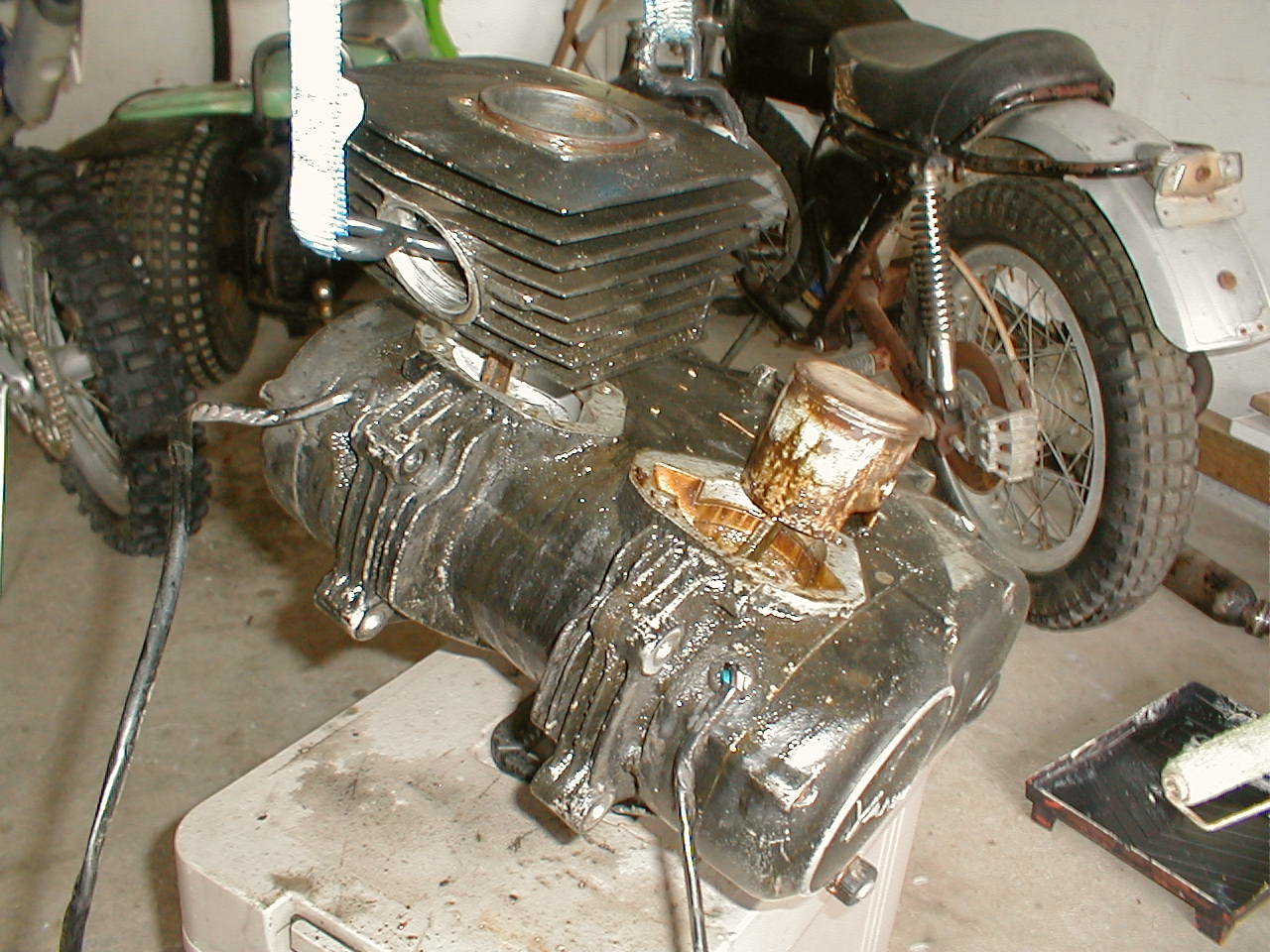

It

doesn't get much worse that this. Hopefully

the

con rods and main bearings are usable, would

have

to split the cases to replace those. Now the

wrist

pins have to come out, and there is no reason

to

believe they will be any easier than the pistons.

"Free at last! free at last!

Thank God Almighty, we are free at last!"

The cylinders will be cut .20 over or replaced,

and new pistons will be used

for the rebuild. See the top left (from front)

piston? Big dry spot, even after almost two

weeks of soaking in kerosene.

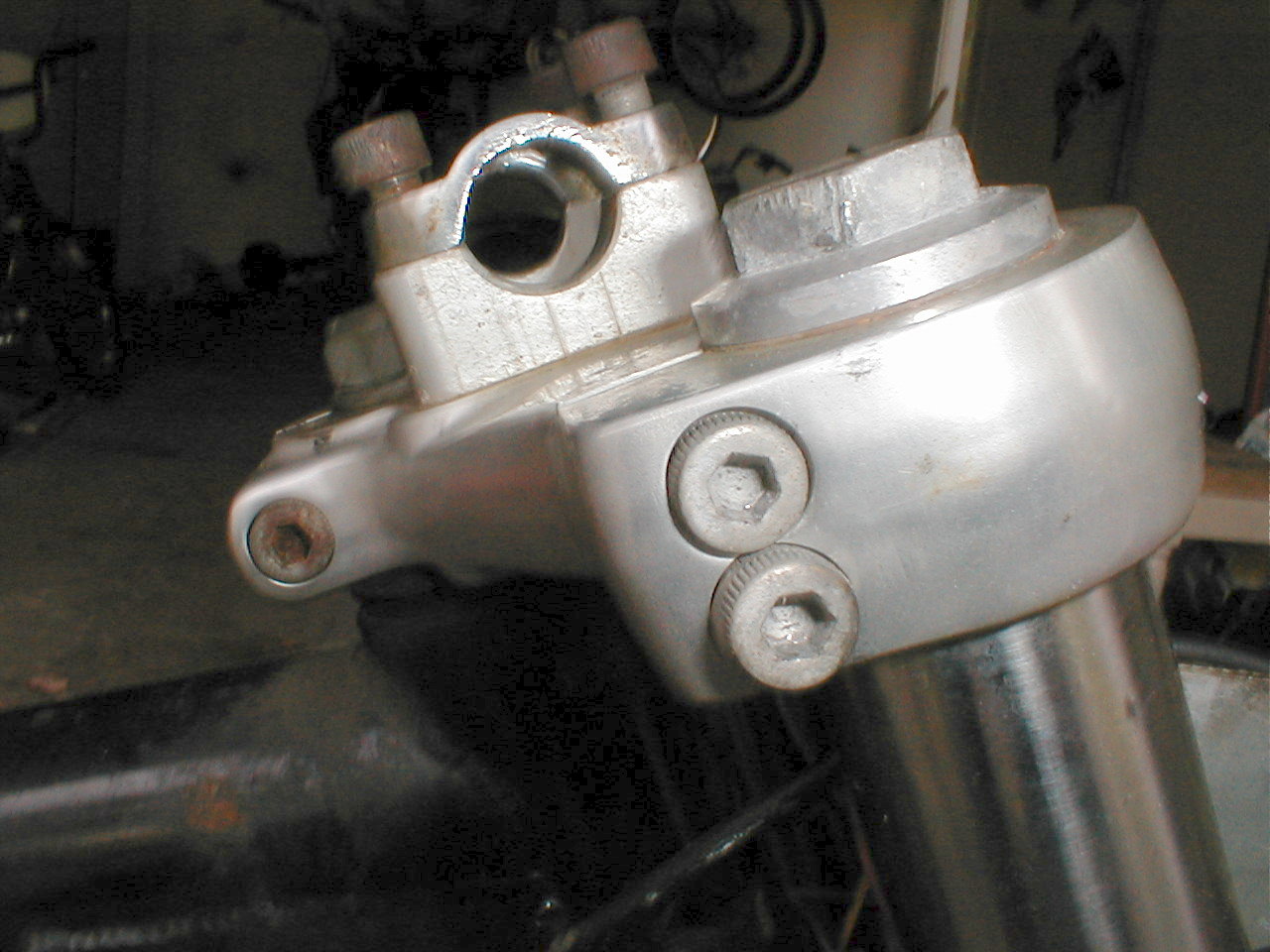

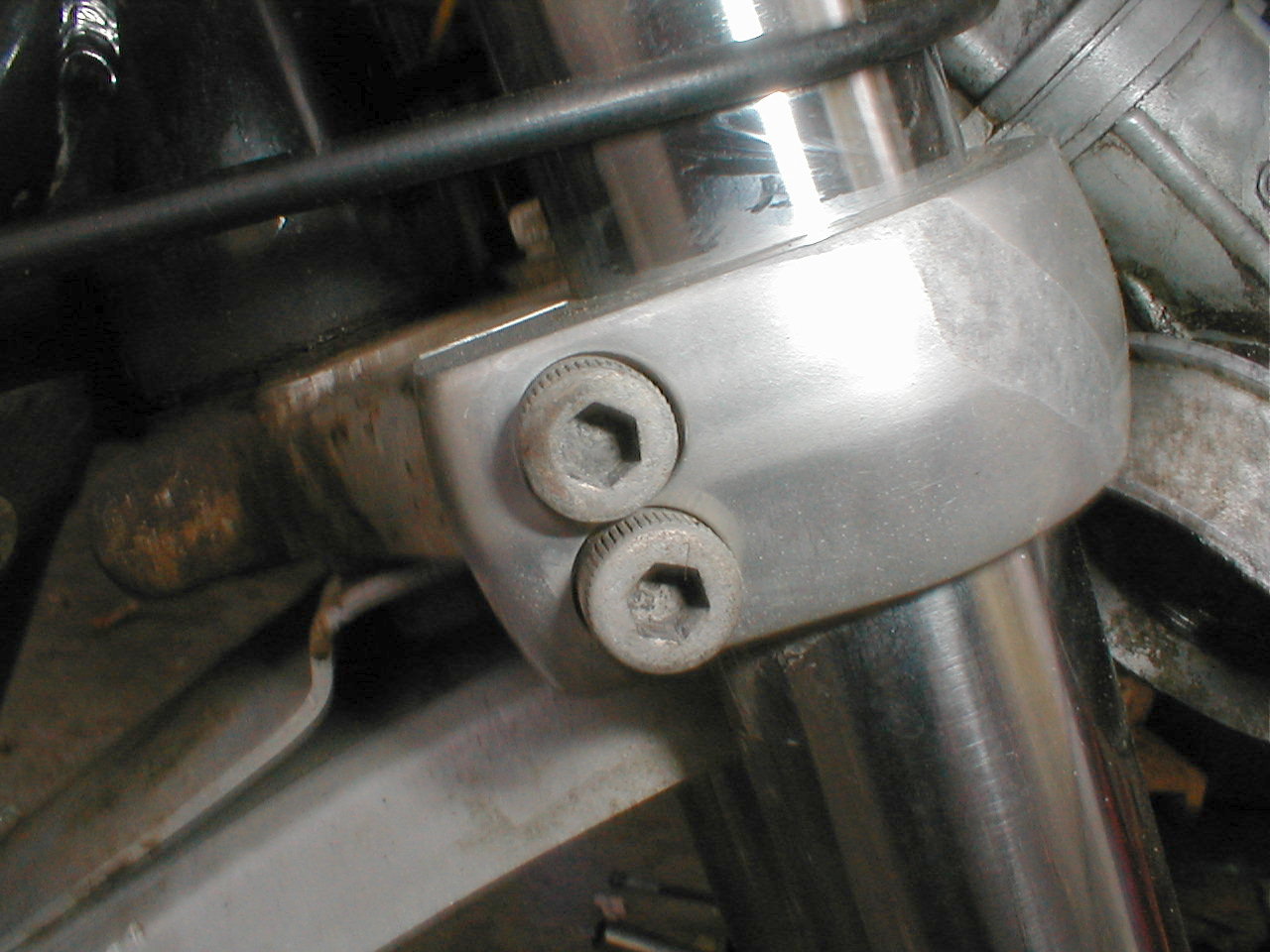

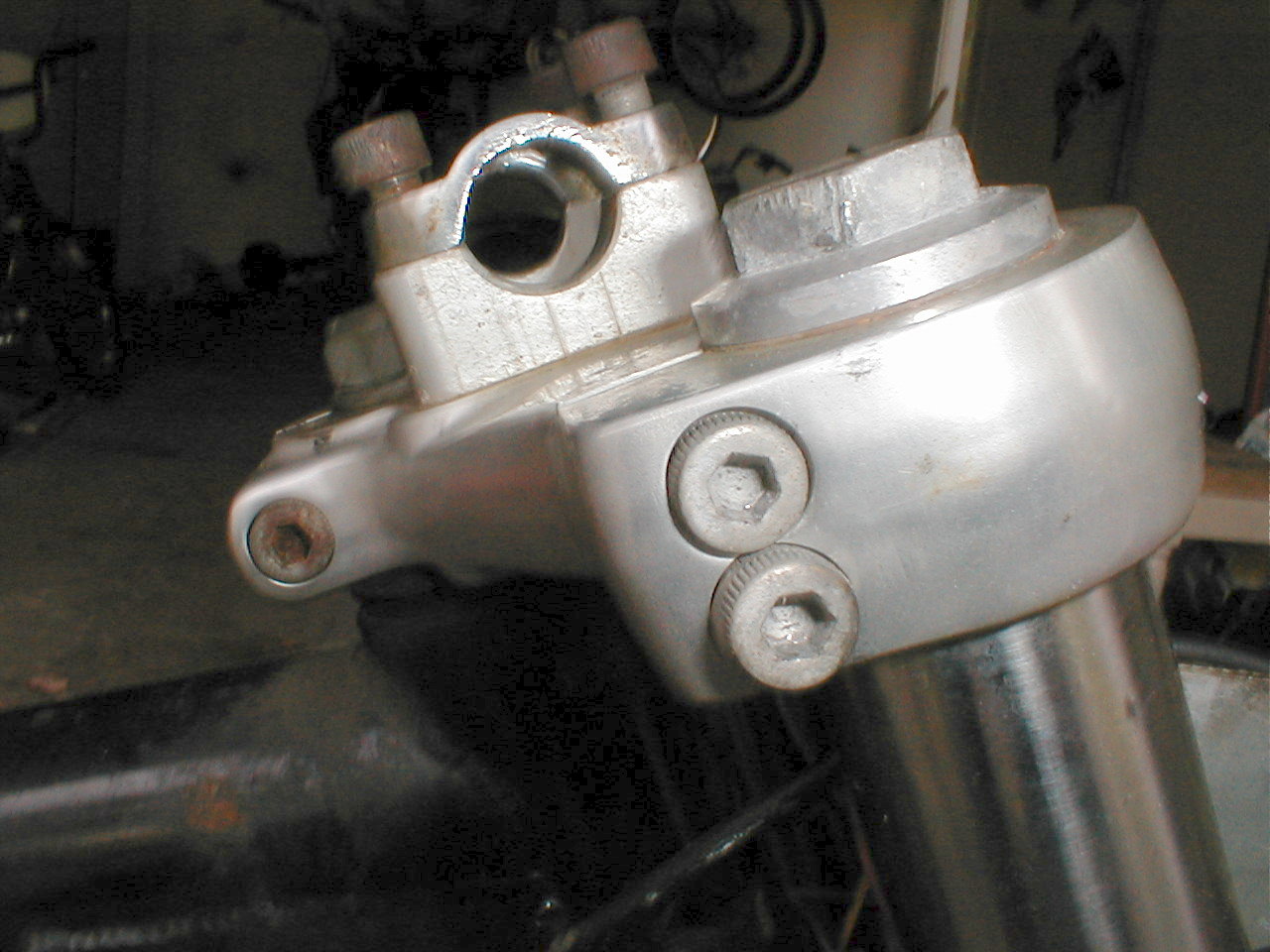

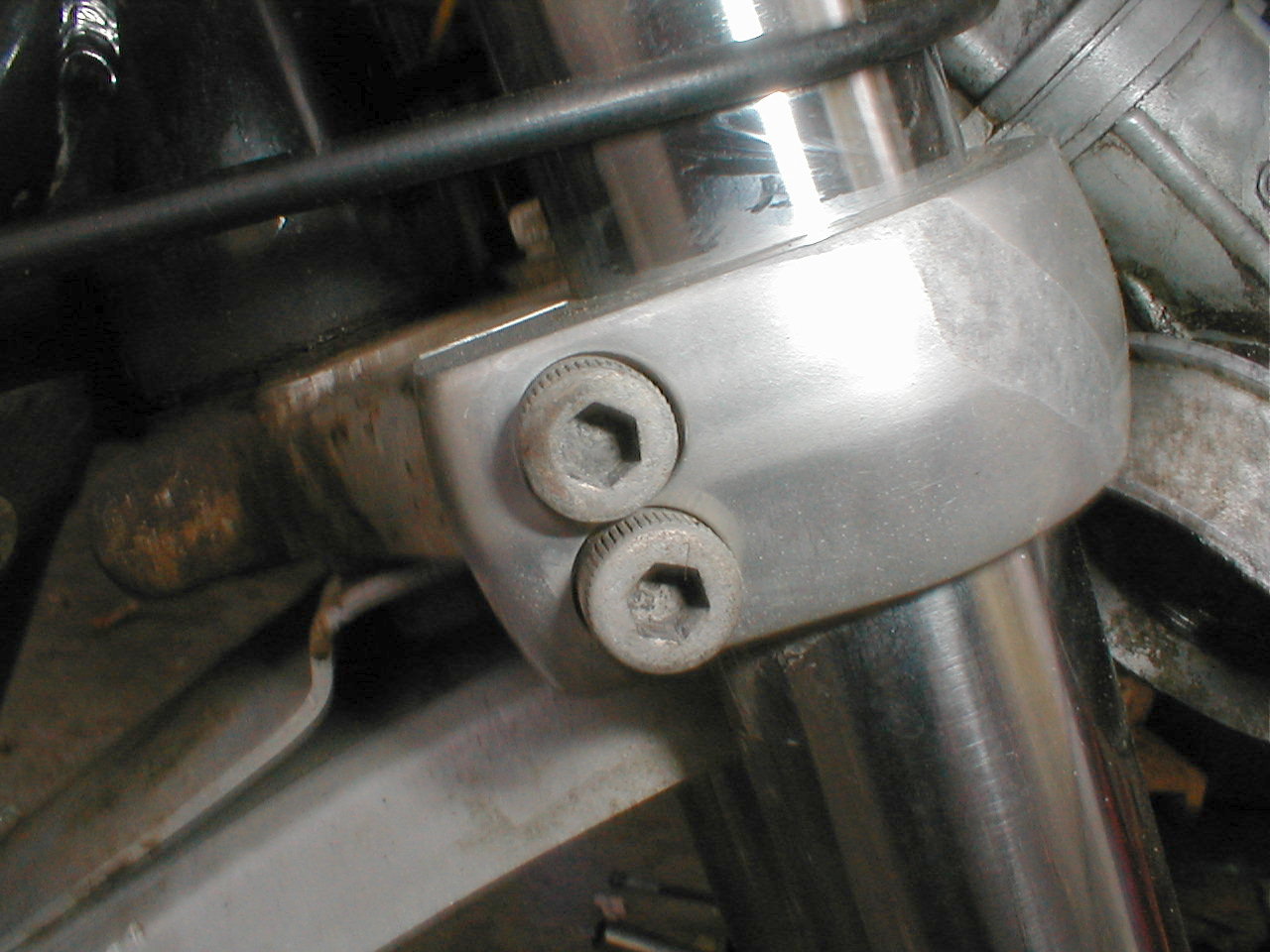

Who

can guess how many hex wrenches got broken

before

these triple clamp bolts came out?

Winner

gets a prize (not really).

Guess

again, it was more than that.

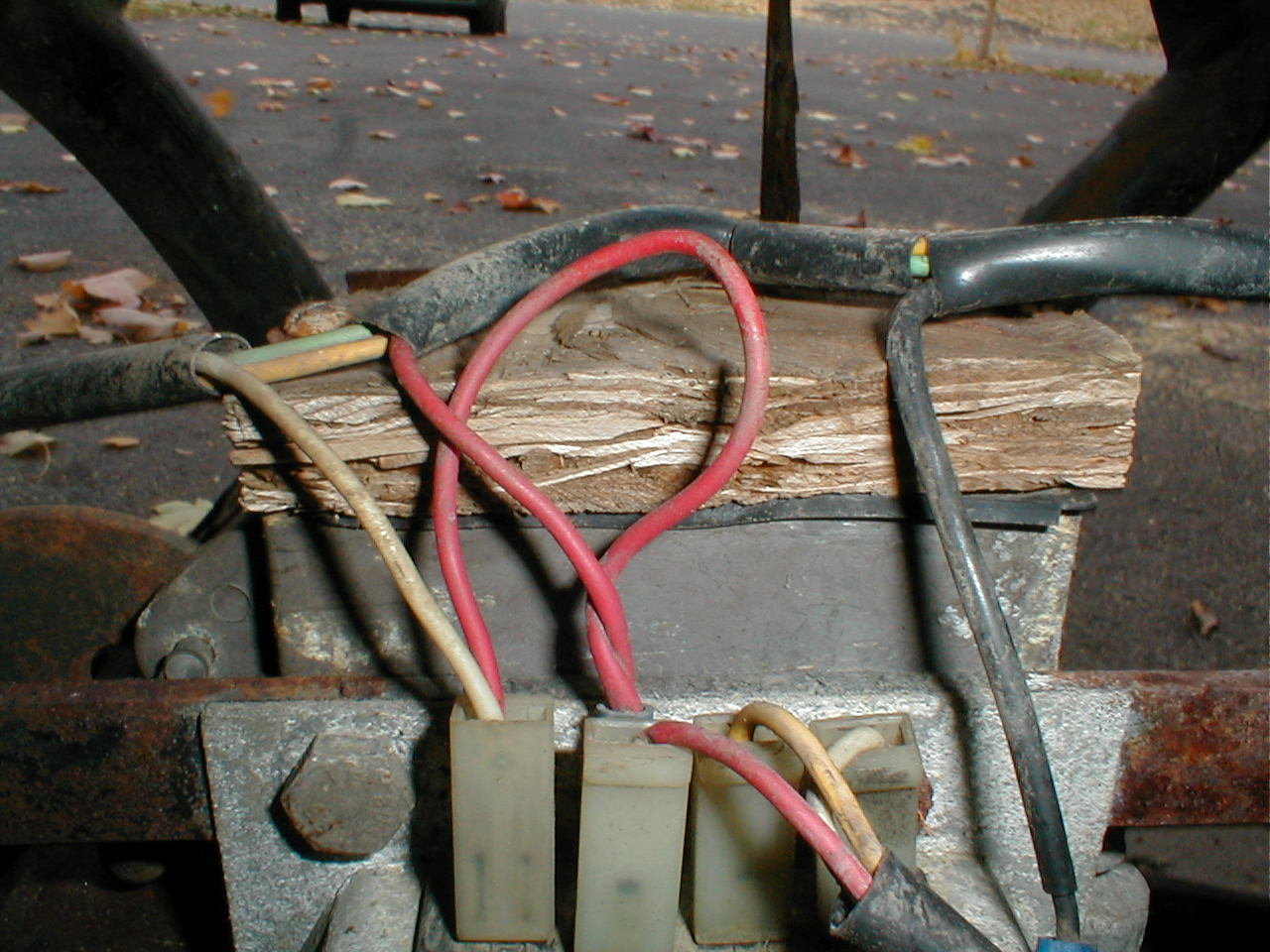

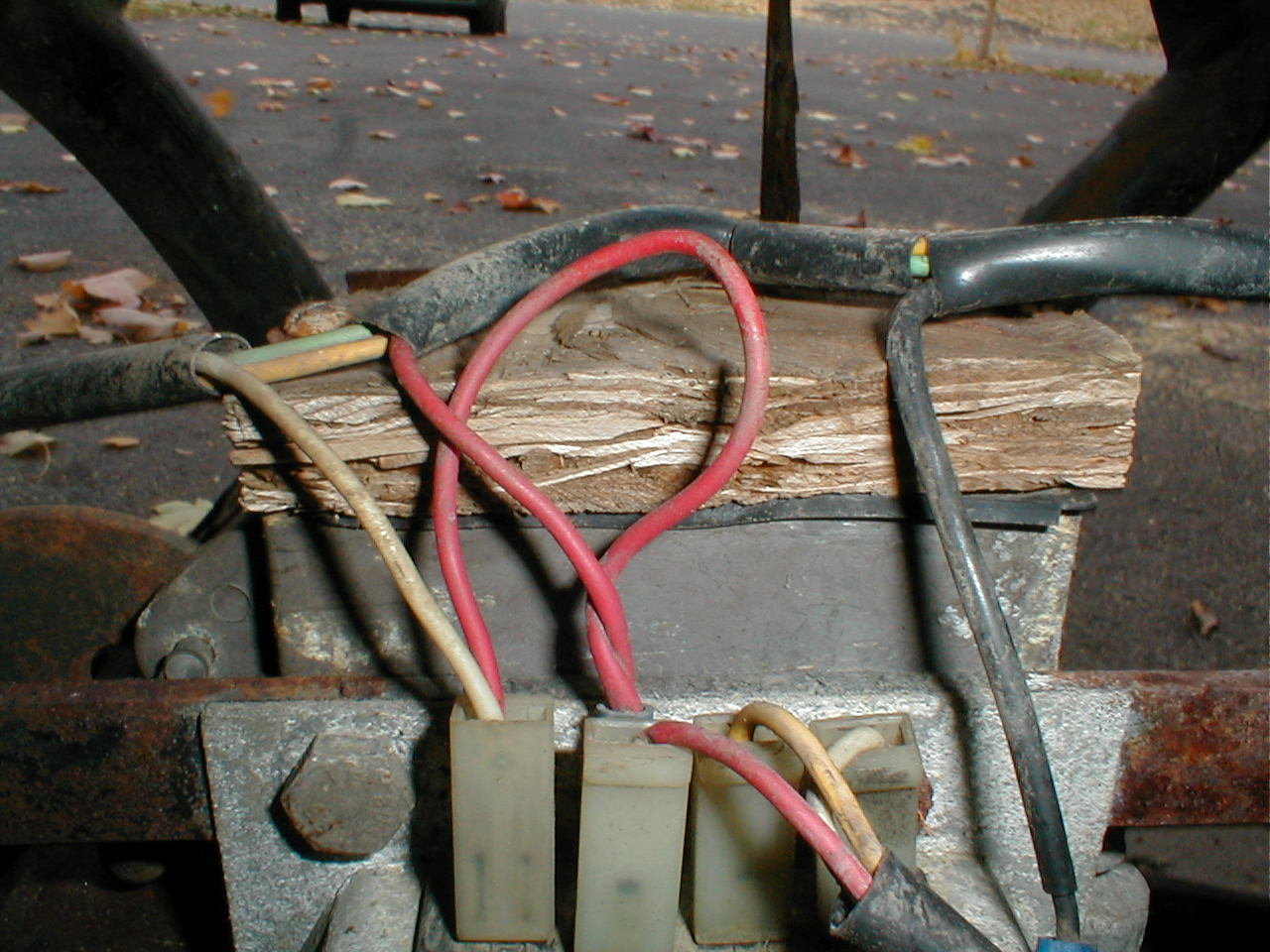

If

you needed a new cover for your brake

fluid

reservoir, wouldn't fiberboard be your

first

choice for a replacement?

This

most likely lasted at least a day before

beginning

to let moisture into the brake fluid,

lines,

and cylinder, creating the rust and

corrosion

that is there now.

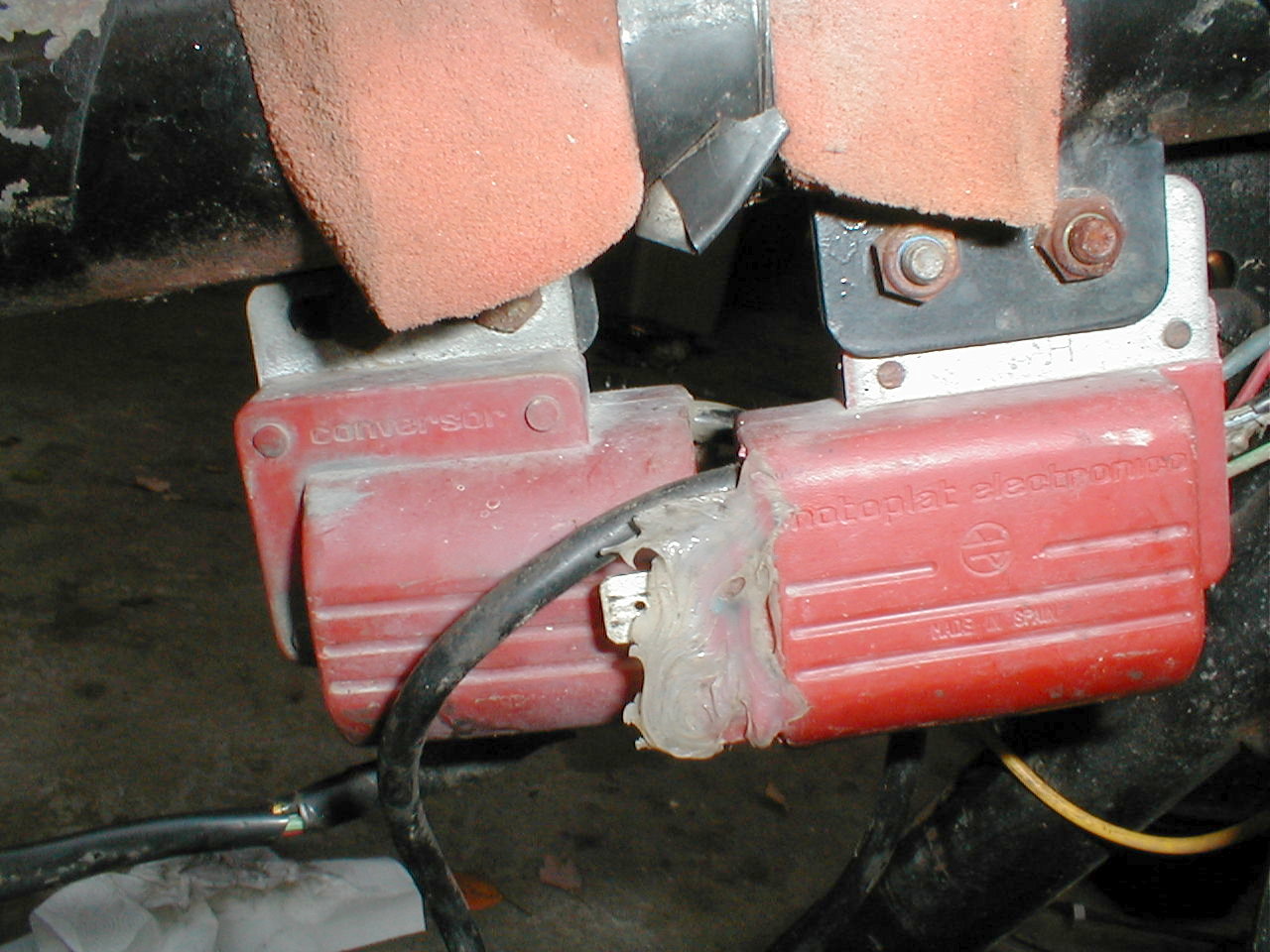

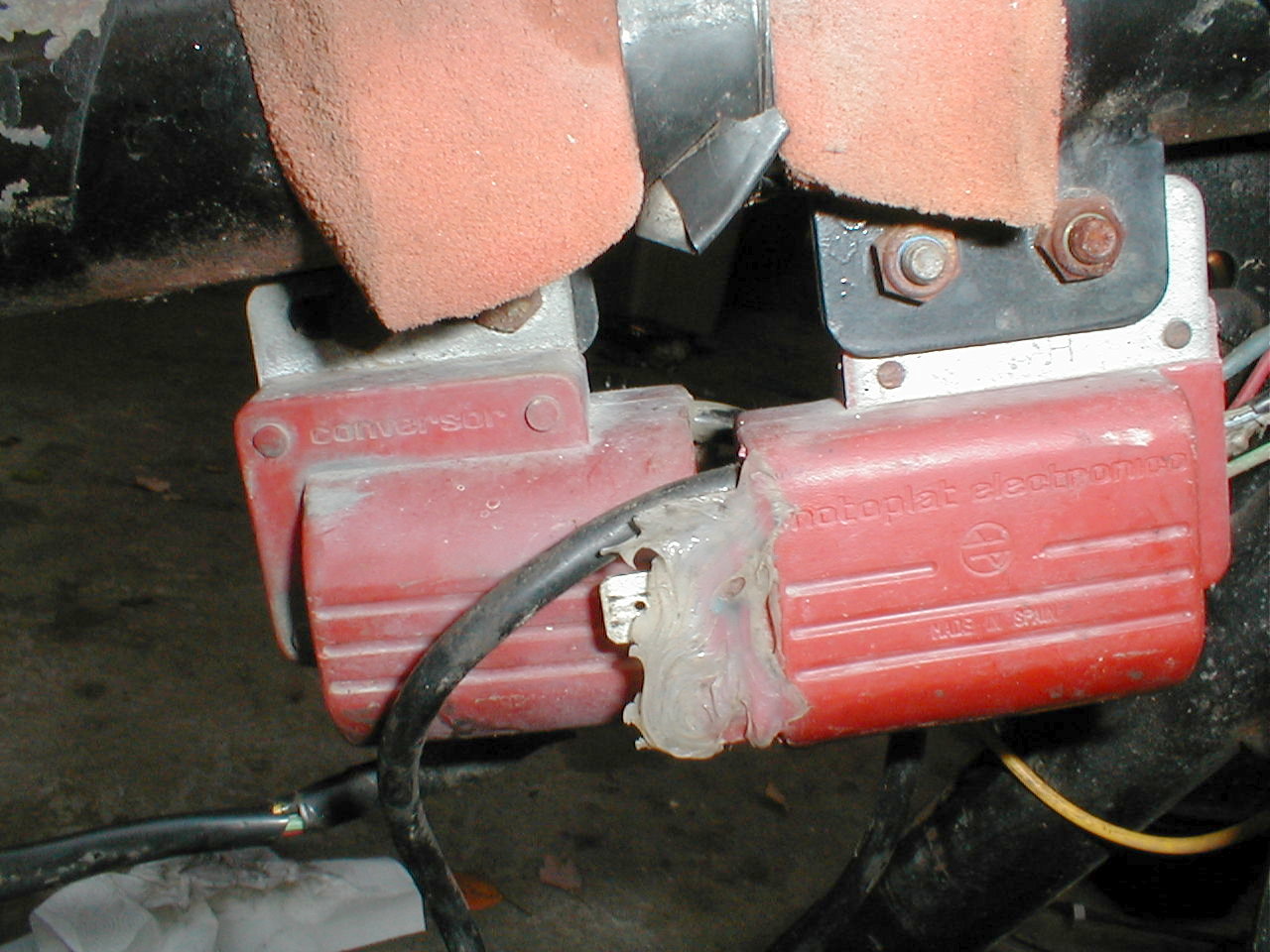

Looks

like someone has been messing with these

coils

already, not reassuring that these will light

the

fire when the engine rebuild is complete.

Battery

boxes always seem to be rusty, either

due

to the acid leaking out, or the fumes in

the

area, or the flow of electric. This one

will

need a good sandblasting, primer coat,

and

final coat of paint.

The

speedo was taken apart, cleaned, oiled,

and

checked for operation. It looks like the

odometer

and trip meter are history, so the

drive

gears were taken out for them.

The

speedometer looks to be working OK,

that's

all that is needed for now

anyway.

Replacement glass will be found,

and

the seal ring fastened back on to make

it

as water resistant as possible.

Just

about ready for sand blasting here. All black

paint

and rust to come off, replaced by Yankee

Silver

all around, even the nuts and bolts. If they

look

better in black, they can be changed later.

Return Page 2

3

4 5

6 7

8 9