1973

Yankee Restoration Project

Pictures

taken 11/25/2003

Time

to open up the cases and inspect

for

damages.

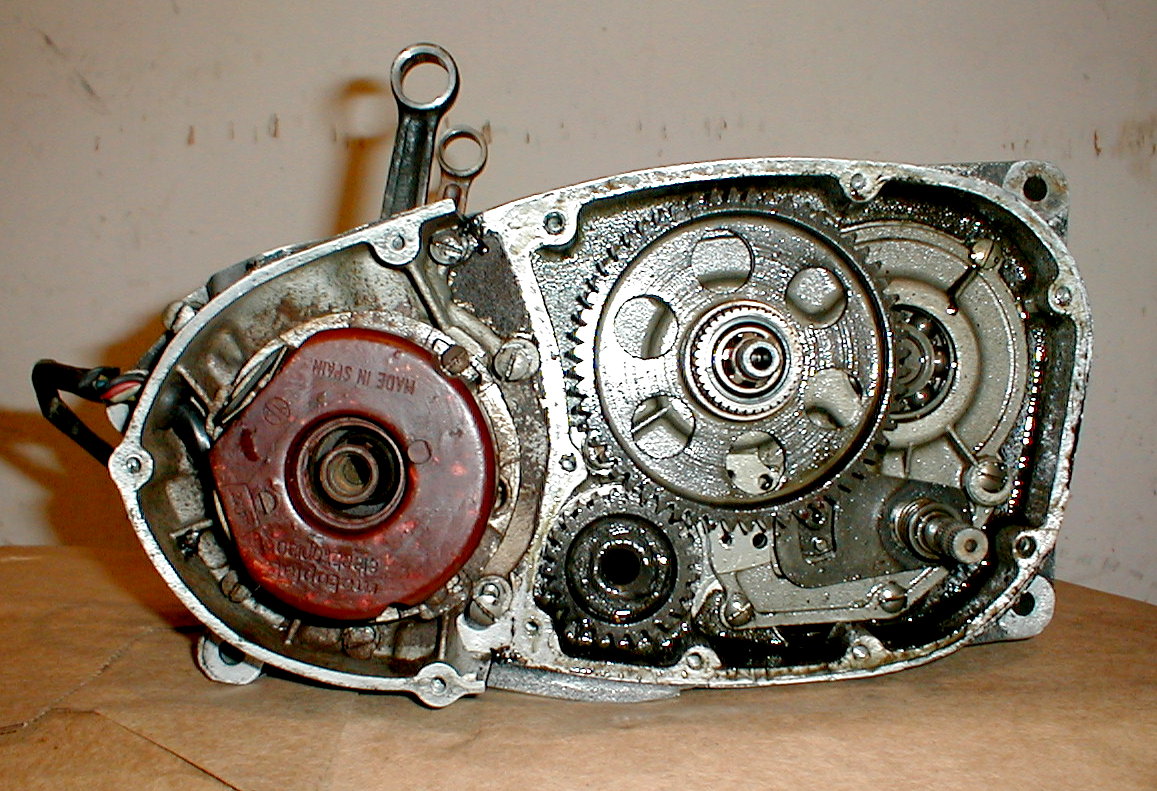

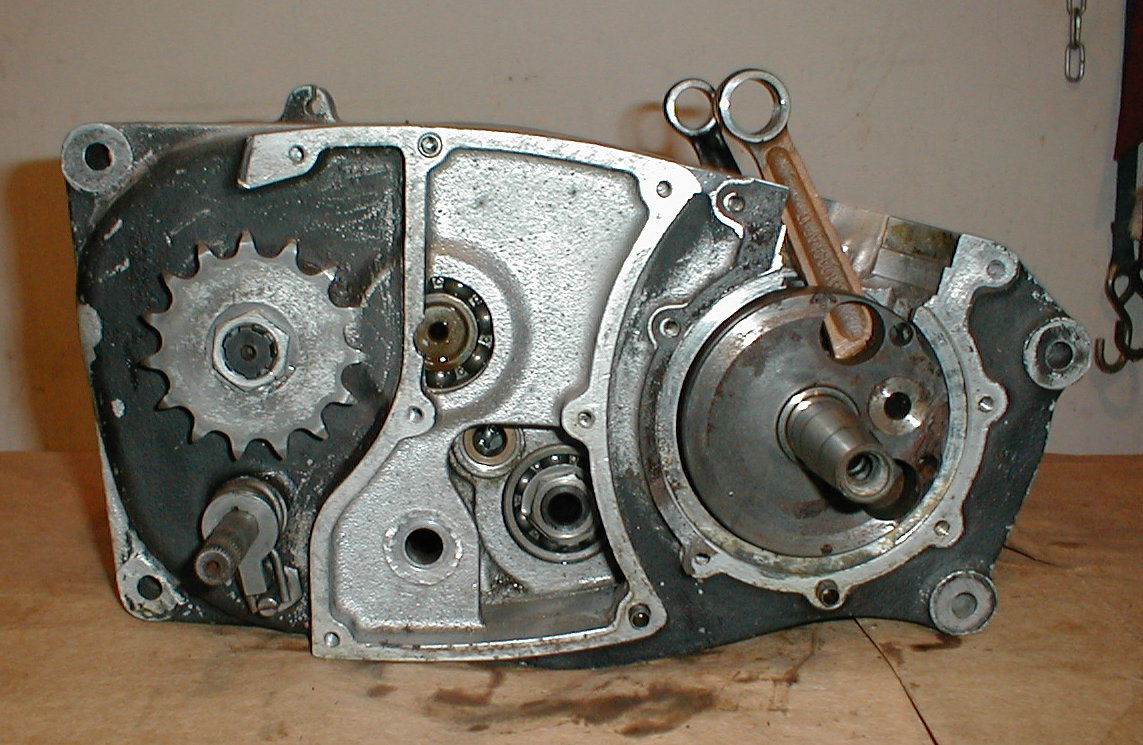

Left

side Motoplat looks OK, that doesn't

say

much about how well its going to work.

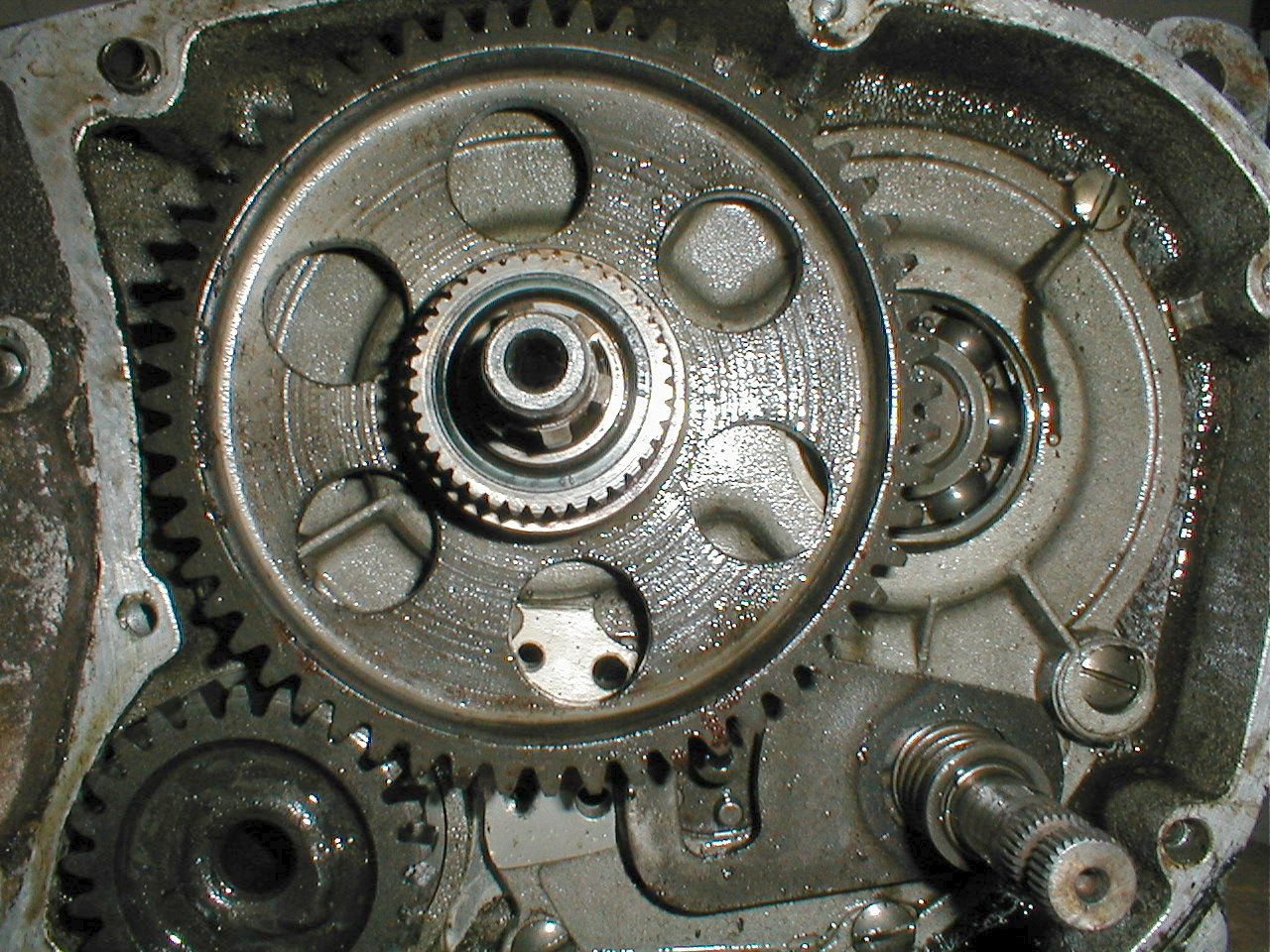

Primary

drive gear allows reduction, lower

left

gear is jackshaft driven.

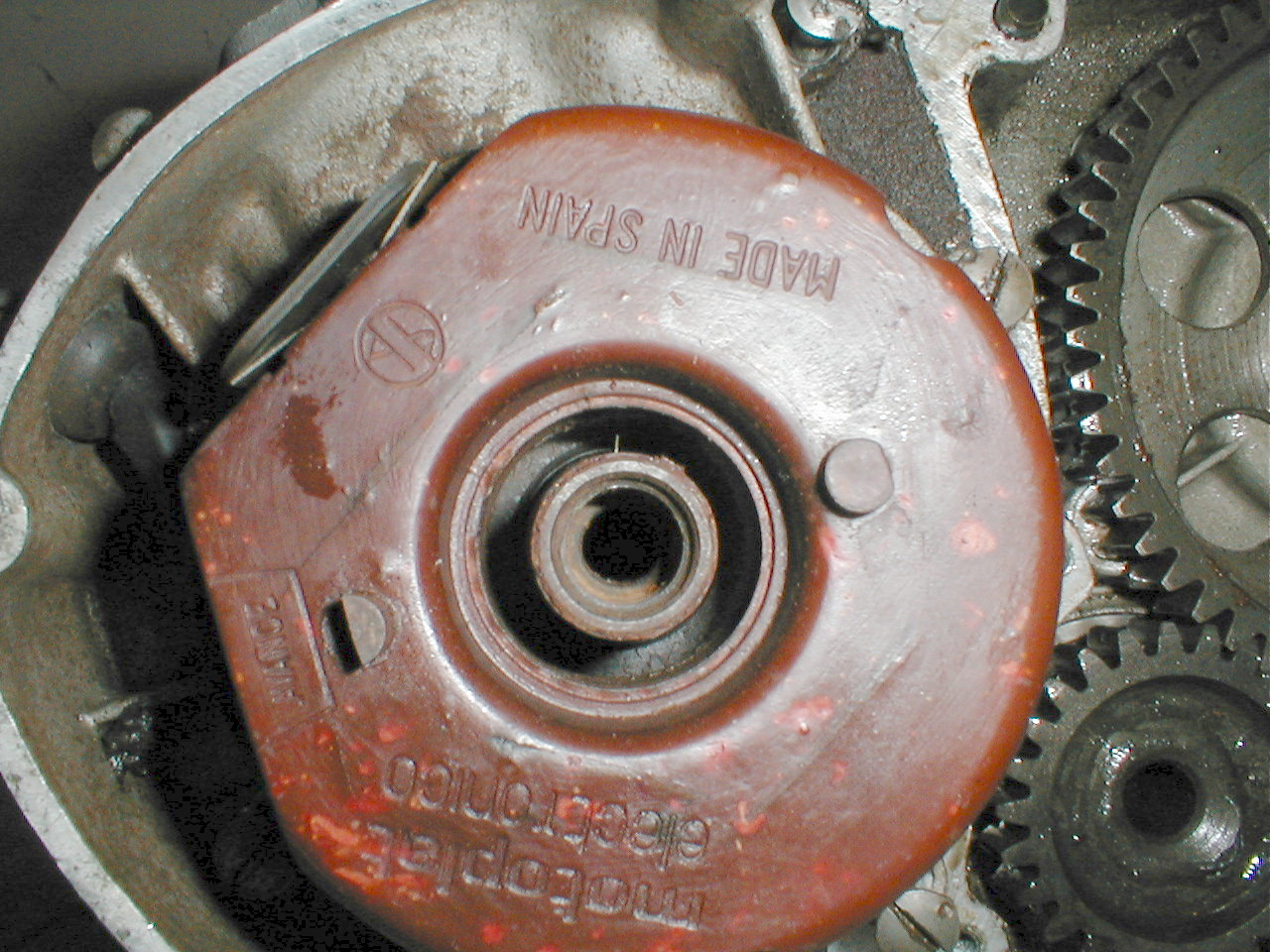

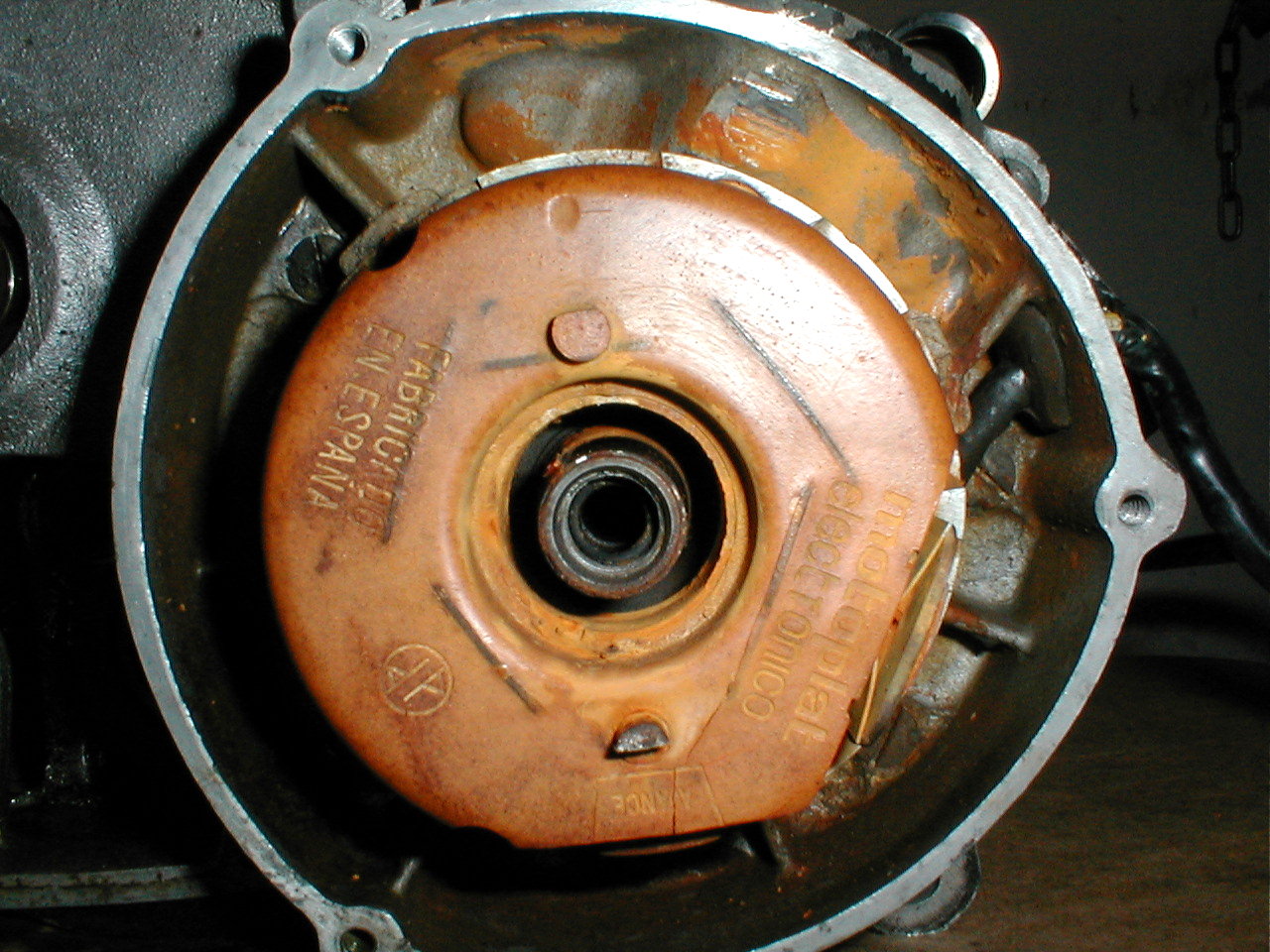

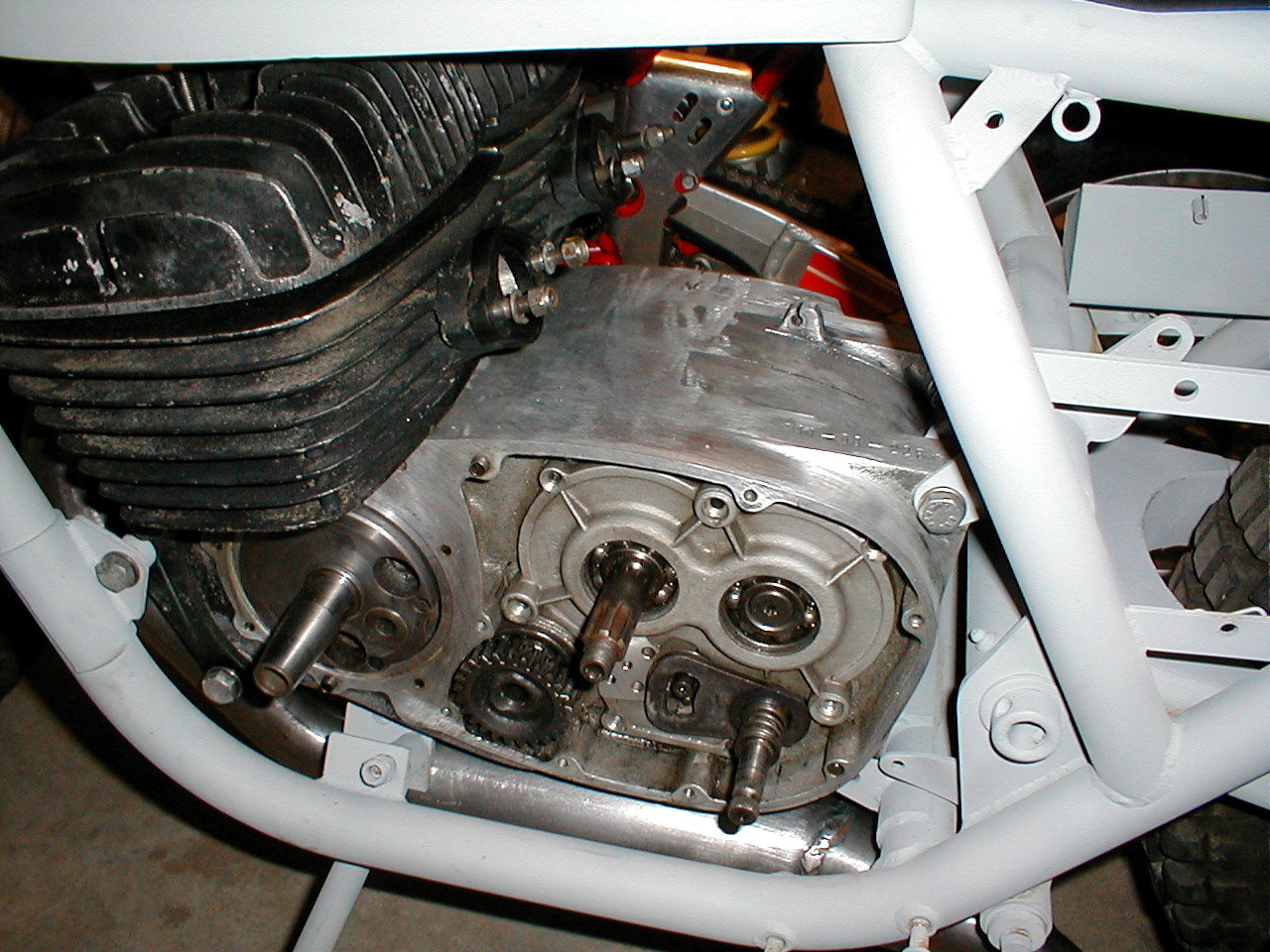

Left

side Motoplat, as with most other

components,

left side showed more

damage

than right. This side had a

coating

of rust that turned the

ignition

system almost orange in color.

Right

side covers off, showing a classic

Yankee

design problem, that is, if the

bike

throws a drive chain, there is a

good

chance it will wedge, and crack

the

engine case, requiring welding

and

machine work to repair.

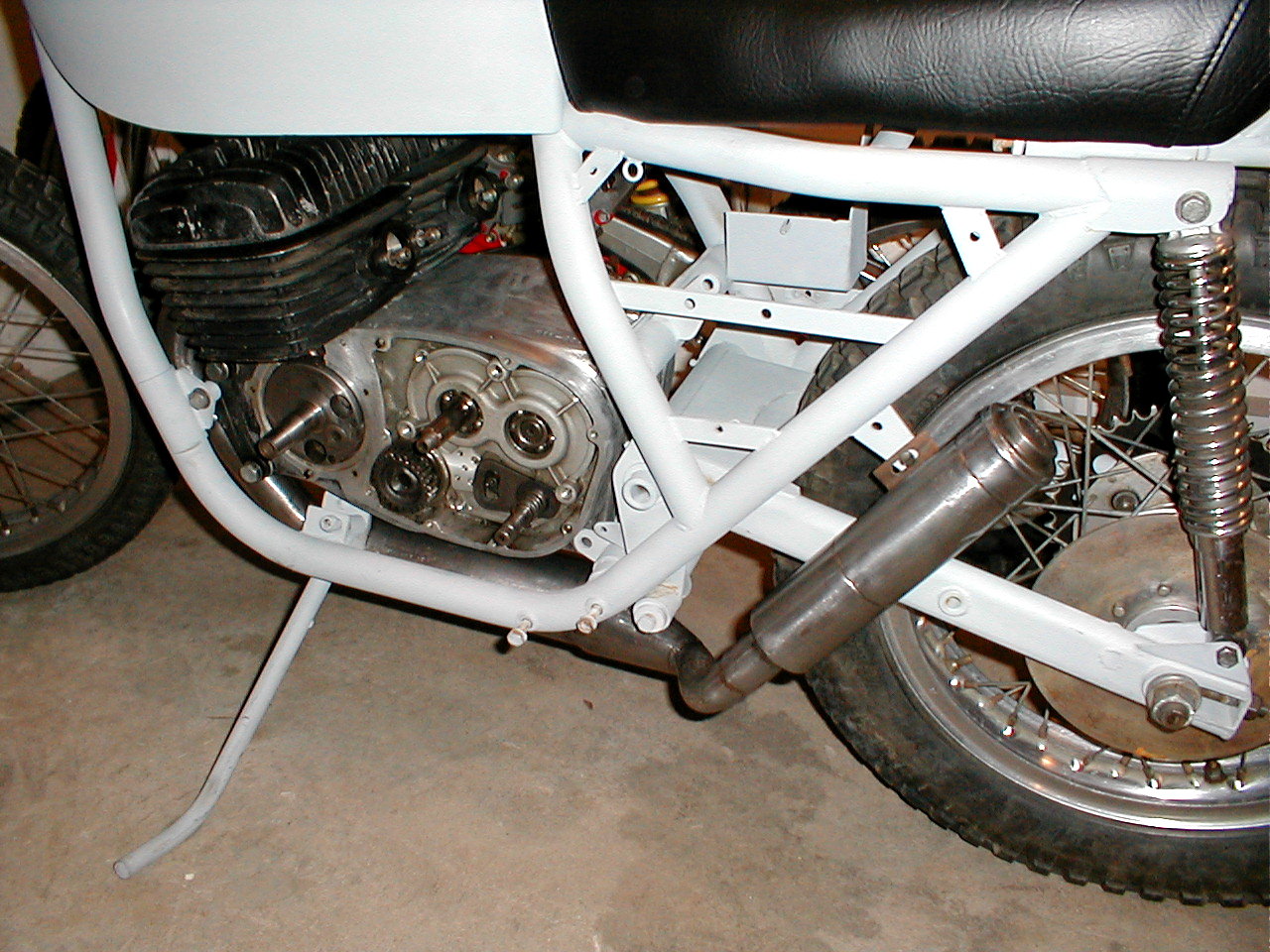

New

Renthal bars have been added to the

bike,

big difference, lower rise and

not

as swept back as the old bars.

There

are a few options for how the bike can

be

restored. First - factory original, very

little

discussion needed there, this is most

likely

the way it should be done. There is no

doubt

that a quality restoration to

factory

is the most valuable bike to have.

But,

I had a factory bike for 2 years, and now

am

thinking about some changes to make the

bike

suit me a little better.

One

option is to switch the bike to a 180 degree

firing

order, like a street bike. The engine may

start

a little easier, make more power higher up

in

the power band, and sound different. With the

factory

expansion chambers, this may be the

ideal

combination for street / trail type of use.

Other

choices include polished cases instead of

painted

black, as in Ossa and Bultaco. The

expansion

chambers may also look good in

chrome,

like some other classic chambers.

They

look good now in polished steel.

Another

step would be to replace the IRZ

carbs

with Mikunis. Again, easier

starting

both hot and cold, more reliable,

and

easier to service / tune.

Once

the bike is finished, it will be my daily

rider,

so it has got to be reliable. If it's

possible,

the electrical system will be

upgraded

from 6 volt to 12 volt, and a

bright

halogen headlight added fo safety.

Part

of the reason for these pictures is to

help

sort through these options, and determine

what

might look best on the finished bike.

One

of the steps to add to the reliability and

durability

to the motor will be to have the main

bearing

throws machined to accept larger

connecting

rods. The Ossa 250 engine design

started

from a 160 cc motor, and the rods

are

considered to be a weak point for anything

beyond

a mild state of tuning or riding.

Return Page 2

3

4 5

6 7

8

9